In today’s fast-paced world, noise pollution has become a growing concern in homes, offices, industries, and public spaces. Whether you’re designing a recording studio, upgrading an office, or improving the acoustics of a restaurant, effective soundproofing solutions are essential. But with so many options available, how do you determine the best company for your soundproofing needs?

What Makes a Soundproofing Company Stand Out?

When selecting a soundproofing company, several factors must be considered to ensure you get the best results. These include:

1. Expertise in Acoustic Engineering

A top-tier soundproofing company should have a team of experienced professionals specializing in building acoustics and soundproofing solutions. Experts such as acoustic engineers and certified senior acousticians ensure that each project is handled with precision.

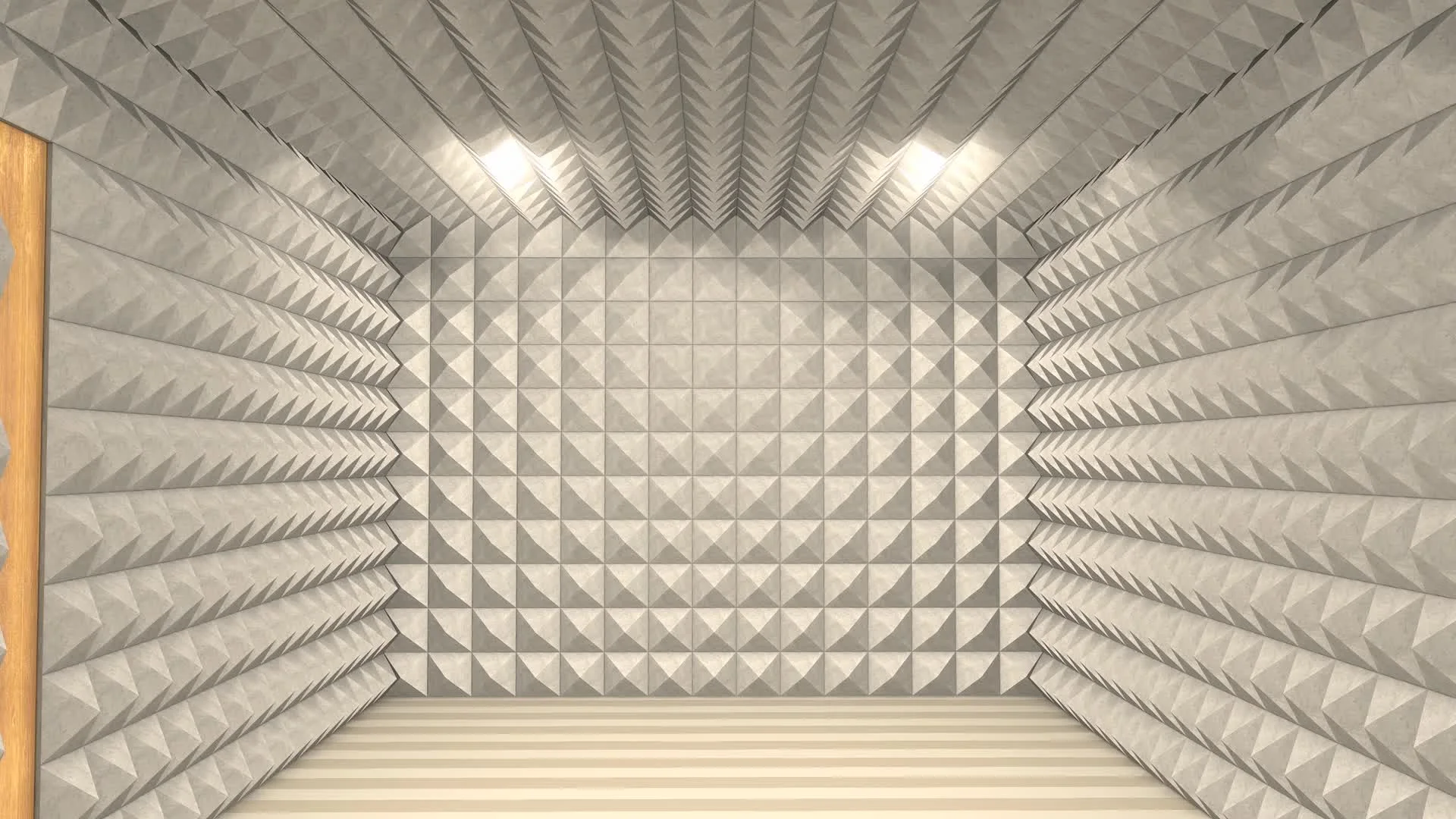

2. High-Quality and Aesthetic Products

Soundproofing isn’t just about reducing noise; it’s also about enhancing the visual appeal of a space. The best companies offer solutions that not only absorb sound efficiently but also add an element of design to the environment.

3. Customization and Innovation

Every space is unique, requiring tailored solutions to meet specific acoustic needs. The leading companies invest in research and development to create customized soundproofing products that match clients’ exact requirements.

4. Advanced Acoustic Simulation Technology

Accurately predicting acoustic performance is crucial. Companies that use cutting-edge software tools to simulate and analyze soundproofing results ensure the highest level of precision in their solutions.

5. Solutions for All Sectors and Budgets

A reliable soundproofing provider should cater to diverse sectors, including recording studios, restaurants, offices, schools, industrial buildings, and residential spaces. Additionally, they should offer solutions in all price ranges to meet different customer needs.

Why Akcoustic is the Best Choice?

Among the top soundproofing companies, Akcoustic stands out for its dedication to delivering clever solutions for every acoustic challenge. With a team of certified professionals from the Institute of Acoustics (IOA) – UK, we provide expert guidance and innovative products designed for maximum efficiency.

At Akcoustic, we believe in blending functionality with aesthetics. Our range of products not only minimizes unwanted noise but also enhances the visual appeal of your space. Whether you need customized acoustic panels, sound barriers, or high-performance insulation solutions, our Research Department ensures every product is designed to meet your exact needs.

With access to the most advanced simulation tools, we guarantee accurate predictions of acoustic performance, helping you achieve the best soundproofing results before installation. Plus, our solutions are available across various price ranges, ensuring there is an option for every budget.

Conclusion

When it comes to soundproofing, quality and expertise make all the difference. Akcoustic is the ultimate choice for businesses and individuals seeking top-notch acoustic solutions. Whether you are looking to improve a workspace, control noise in a busy restaurant, or enhance a professional studio, our innovative products and expert team are here to help.

Get in touch with Akcoustic today and experience soundproofing excellence like never before!